Steel Building Components

Built-Up

Paramount’s Build-up beams are manufactured with continuous submerged arc welding process for web & flanges on single side/double side welding as per codal requirements. We manufacture different sections of Beams like “H,T,I” BOX and PLUS type.

Built-up beams are made of different sizes of plates which are riveted, bolted & welded. A built-up beam is also known as compound beam which are used when the span, load and corresponding bending moment are of such magnitudes that rolled steel beam section becomes inadequate to provide required section modulus.

The fabrication process of Built-up is equipped with the below machinery

Shearing

Machine

Shearing

Machine

Oxy Fuel

Multi Torch

Oxy Fuel

Multi Torch

CNC 5 stroke plate Punching & Drilling machine

CNC 5 stroke plate Punching & Drilling machine

Sub arc Continuous Machine

Sub arc Continuous Machine

SAW Welding & MIG Welding Machine

SAW Welding & MIG Welding Machine

Shot Blasting Machine

Shot Blasting Machine

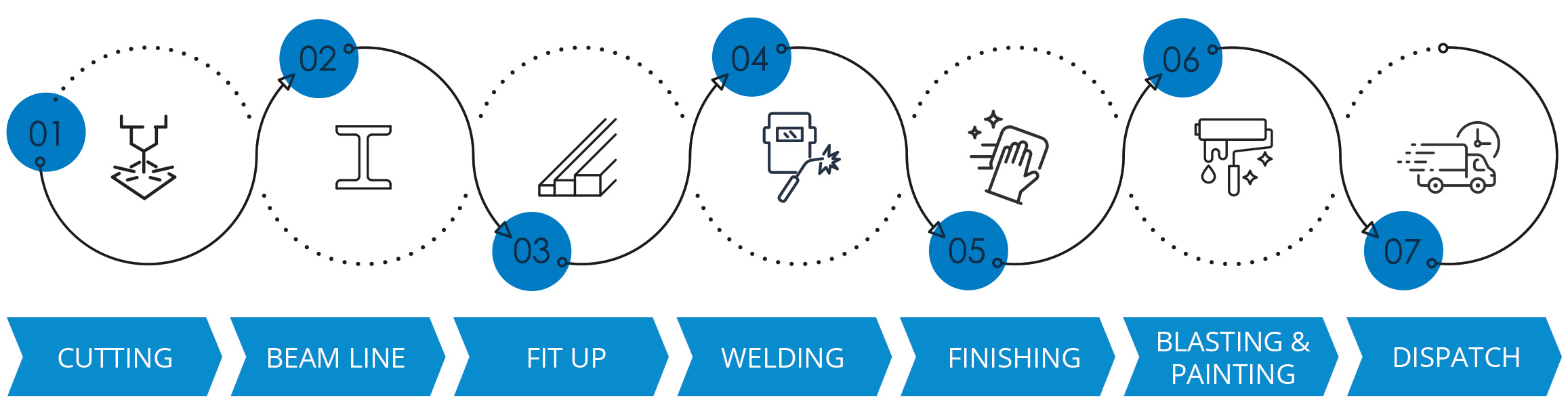

Process Flow

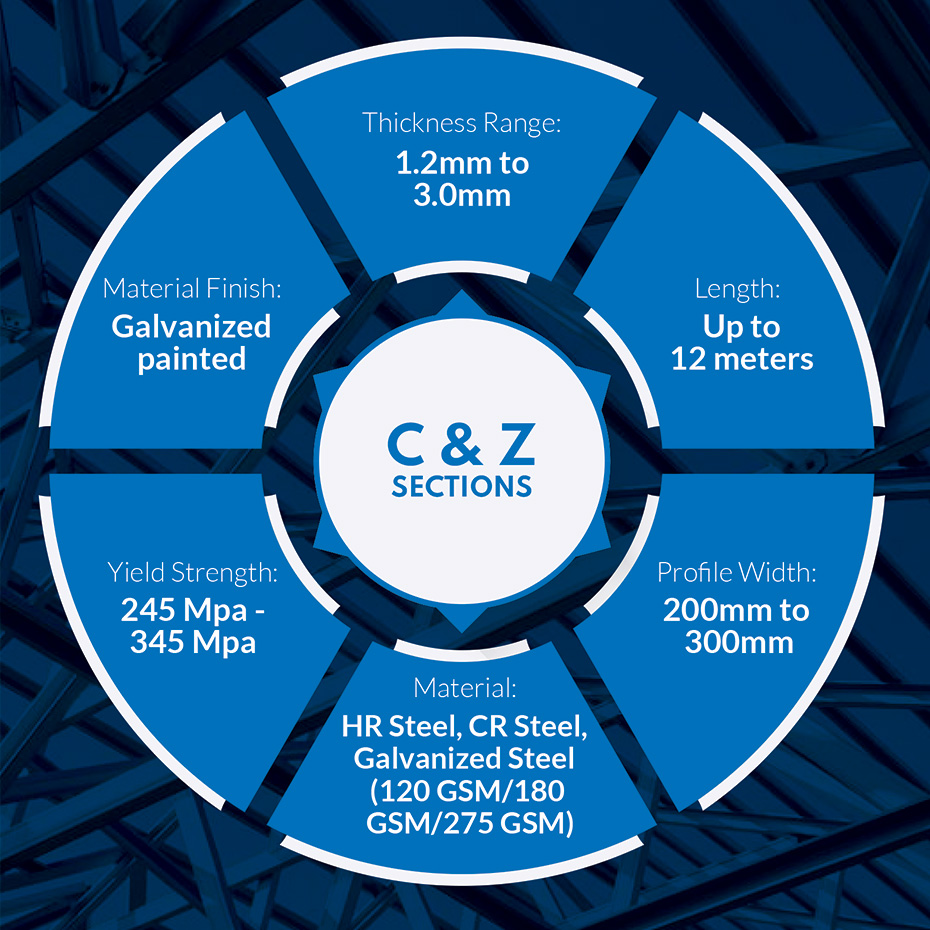

Purlins

We use Cold formed steel as the basic material and considering the higher strength to weight ratio of CRF sections. Purlins have gained wider acceptability in a numerous of construction activities. They are used in construction of steel buildings, industrial ware houses, a PEB etc., Cold formed Purlins are well accepted by architects, structural consultants all over India and rest of the world.

We supply purlins in exact cut to length and as per the requirement for easy erection and to avoid wastage at site. Z-Purlins & C-Purlins are available in a range of 1.2 mm to 3.0 mm. Sections can be supplied in various grades of steel to meet the exact requirements. Paramount allows flexible design options.

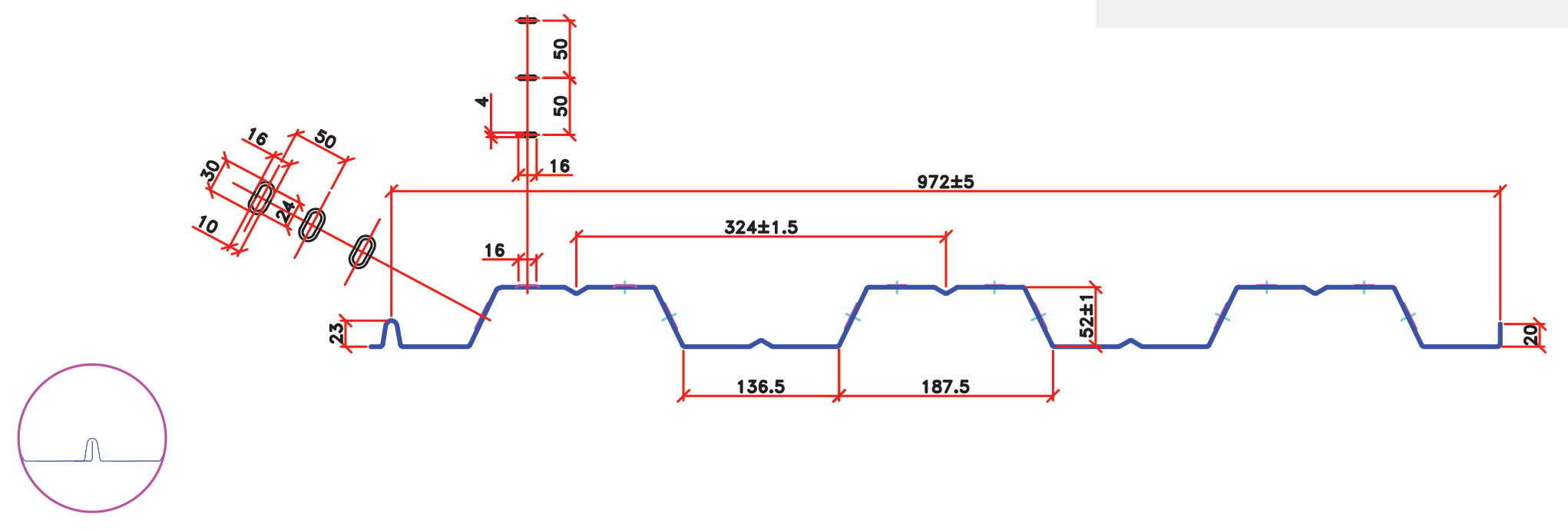

Paradeck - 52

ParaDeck 52 is used as a composite floor system. The steel deck profile sheet has a ribbed profile with embossment to interlock with concrete slabs, creating a reinforced concrete slab that serves dual purpose of permanent form, positive reinforcement and reliability.

The composite slabs have now become a common use in construction of floor decks in major buildings. In common slabs, the profile sheet is used as permanent form work and as tensile reinforcement. In this composite slab, there is 30% saving in concrete material, resulting in reduced structure weight. It favours fast and easy construction and also it proves to be economical. Paramount deck sheeting is special profiled with ribbed profile to interlock with concrete slabs.

Benefits

- Promotes speedy construction for shorter lead times.

- Contributes to fewer concrete usage use.

- Reinforces the durability of your building.

- Light weight and doesn’t require any support, which considerably reduces the use of concrete & slab thickness.

- Deck can be used as working platform during construction.

Specifications

| Thickness(mm) | |||

|---|---|---|---|

| 0.6 | 0.8 | 1.0 | 1.25 |

| Unit weight (Kg/m2) | |||

|---|---|---|---|

| 6.51 | 8.27 | 10.3 | 12.9 |

| Joist to Joist Spacing(mts) | ||||

|---|---|---|---|---|

| Loading(KN/m2) | ||||

| 1 | 1.25 | 1.50 | 1.75 | 2 |

| 15.43 | 9.87 | 6.86 | 5.04 | 3.86 |

| 23.3 | 14.91 | 10.36 | 7.61 | 5.83 |

| 31.91 | 20.42 | 14.18 | 10.42 | 7.98 |

| 40.07 | 27.6 | 19.3 | 12.6 | 10.3 |

Profile

Paraclad Sheeting

Specifications

- Aluzinc coating- AZ150. (AI-55%, Zn-43.4%, Si-1.6%)

- Tensile Strength – 550 MPA

- Thickness Range –0.47 mm to 0.6 mm

- Effective Width – 1060 mm

-

Paint Type

(a) Regular Modified Polyester (RMP)

(b) Silicon Modified Polyester (SMP)

(c) Polyvinyl Difluoride (PVDF) - Paint Thickness (Top): 18 to 20 microns

- Paint Thickness (Bottom): 5 to 7 microns Alkyd back coat

Standard Sheeting Colors

OFF WHITE

MIST GREEN

BRICK RED

SKY BLUE

TAURUS BLUE

TURQUOISE BLUE

Profile